Blog

- Home

- Blog

3 Ton Overhead Crane: Efficient and Safe Lifting Solution for Light-Duty Material Handling

A 3-ton overhead crane is designed for light to medium-duty lifting tasks and is widely used in machinery manufacturing, warehouse logistics, metal processing, and equipment assembly. It features a compact structure, stable operation, and simple controls. The crane is easy to install, highly adaptable, and offers low maintenance and excellent energy efficiency. It meets daily lifting and material handling needs and is one of the most cost-effective solutions for modern light-duty operations.

Types Of 3-ton Overhead Cranes

Types of 3-ton overhead cranes

Core Advantages and Performance Features of a 3-Ton Overhead Crane

A 3-ton overhead crane is engineered for efficiency, safety, and economy. It supports continuous lifting tasks under light-duty conditions. Its key advantages include:

- High lifting efficiency: The crane supports single-hook operation and single or dual-speed control. With VFD technology, it offers smooth and precise positioning while reducing impact loads.

- Enhanced safety performance: The system includes overload protection, emergency stop, and upper and lower limit switches. These functions monitor operation and prevent risks.

- Compact structure with minimal space requirements: The crane uses a lightweight and optimized design. Its compact layout improves adaptability and allows flexible installation in various plant settings.

- Smooth operation, low noise, and excellent energy savings: The electrical system uses high-efficiency drives. Mechanical components are well matched for long-term stable performance, reduced maintenance, and lower operating costs.

Main Application Scenarios for a 3-Ton Overhead Crane

Thanks to its lightweight design and flexible configuration, the 3-ton overhead crane is suitable for a variety of industrial scenarios, including:

- Assembly line lifting and material transfer: Ideal for fast lifting and precise positioning between assembly processes.

- Workpiece handling and machine loading: Suitable for CNC machines, lathes, welding stations, and similar workstations.

- Warehouse logistics operations: Used for sorting goods, pallet handling, and light material lifting.

- Metal, plastic, and wood processing workshops: Supports fast movement of materials and semi-finished products.

- Electrical equipment and light-industry production lines: Fits automated workflows and handles small to medium components.

- Maintenance shops and laboratory lifting needs: Enables equipment repair, parts disassembly, and sample lifting in precision environments.

Price of a 3-Ton Overhead Crane

|

Product |

Span (m) |

Lifting Height (m) |

Power Supply |

Price (USD) |

| 3-ton single-girder overhead crane |

7.5–28.5 |

6–30 |

220V–660V, 50–60Hz, 3-phase AC |

$1920–6910 |

| 3-ton low-headroom single-girder overhead crane |

7.5–28.5 |

6–30 |

220V–660V, 50–60Hz, 3-phase AC |

$2010–7290 |

| 3-ton underslung single-girder overhead crane |

7.5–31.5 |

6–30 |

220V–660V, 50–60Hz, 3-phase AC |

$1920–6910 |

| 3-ton offset-trolley single-girder crane |

7.5–31.5 |

6–30 |

220V–660V, 50–60Hz, 3-phase AC |

$3060–12420 |

| 3-ton FEM single-girder overhead crane |

7.5–28.5 |

6/9/12m or custom |

220V–660V, 50–60Hz, 3-phase AC |

$4480–9950 |

| 3-ton manual single-girder overhead crane |

5–14 |

3–10 |

220V–660V, 50–60Hz, 3-phase AC |

$1005–1600 |

| 3-ton grab bucket overhead crane |

4.5–28.5 |

13/16m or custom |

220V–660V, 50–60Hz, 3-phase AC |

– |

| 3-ton explosion-proof single-girder crane |

7.5–28.5 |

6/9/12m or custom |

220V–660V, 50–60Hz, 3-phase AC |

– |

Note: Prices updated in November 2025. Actual prices may vary due to raw material costs and market conditions. Final prices shall follow HSCRANE’s official quotation.

For detailed pricing or technical consultation, feel free to contact us. We will provide tailored solutions based on your requirements.

How to Choose the Right 3-Ton Overhead Crane

|

Selection Item |

Description |

Recommendation & Typical Applications |

| Lifting frequency and duty class | Duty class (A3, A4, A5, FEM 1Am/2m) defines durability and cycle capacity | Low frequency: choose A3–A4 economical types. Medium/high frequency: select European structure or higher-grade motors and trolleys. |

| Building height and span | Building conditions determine the crane type and runway design | Limited headroom: choose low-headroom cranes. Large spans: use stronger girders. Ensure runway layout matches lifting coverage. |

| Variable-frequency drive needs | Affects smooth operation, positioning accuracy, and safety | Ideal for machining, assembly, and electronic production. Reduces load swing and mechanical shock. Choose VFD as standard for high-precision tasks. |

| Need for low-headroom design | Used in height-restricted buildings to increase lifting height | Provides higher effective lifting height. Reduces building modification costs. Suitable for old plants or compact workshops. |

| Operating mode: single speed/dual speed, electric/manual | Defines handling efficiency and accuracy | Single speed: basic applications. Dual speed: higher stability and precision. Electric operation: ideal for frequent lifting. Manual: for low-frequency use or low budgets. |

| Customized accessories and functions | Improves safety, operability, and adaptability | Anti-sway system improves accuracy. Wireless remote enhances safety. Anti-collision suits multi-crane workshops. Upgraded limiters and overload protection increase reliability. |

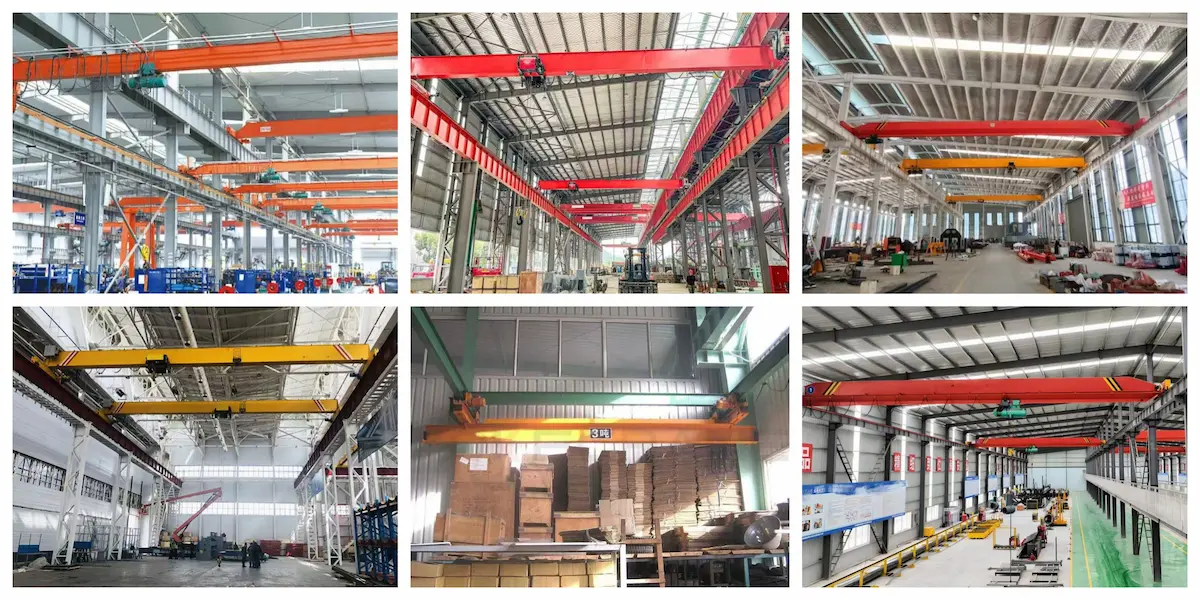

HSCRANE 3-Ton Overhead Crane Case Studies

Case 1: Electronics Manufacturing Workshop in South Africa

HSCRANE supplied a customized 3-ton European-type single-girder overhead crane for a new electronics production line. The crane uses a low-noise drive and high-precision VFD control to ensure smooth and continuous light-load lifting. It also includes overload protection and upper and lower limit switches to ensure safe operation during high-speed and repetitive tasks.

Project Outcome: Production efficiency increased by 30%, workflow became more stable, worker fatigue decreased, and precision component handling became safer, improving overall production performance.

Case 2: Machining Workshop in Cambodia

HSCRANE provided a 3-ton single-girder electric overhead crane for high-frequency workpiece transfer. The crane features an economical configuration that reduces procurement and maintenance costs while ensuring safety and reliability. Its compact structure and stable running performance support continuous 24-hour operation with minimal downtime.

Project Outcome: The crane supported uninterrupted daily operations, reduced production delays caused by equipment stoppage, and delivered strong cost-performance benefits.

HSCRANE Customization and Service Capabilities

- FEM/ISO international standard design: All overhead cranes follow FEM, ISO, and EN standards to ensure long-term safety, stability, and durability. Structural design is strictly calculated to support high-frequency, heavy-duty, or special working conditions with full risk protection.

- Full customization for all 3-ton crane applications: Multiple models can be customized based on headroom, span, lifting frequency, material type, and process needs. Optional features include anti-sway systems, wireless remote control, and trolley anti-collision to support precision assembly, continuous production, and special environments.

- Fast delivery and global service: Modular production and standardized design reduce the manufacturing cycle. HSCRANE provides global installation, commissioning, operator training, and remote technical support. Spare parts are fully supplied with fast response to ensure long-term stable operation.

- Complete technical documentation: Each crane includes structural calculations, installation drawings, electrical schematics, manuals, and CE certificates. Customized drawings or parameter reports can be provided for project planning and engineering approval.

3-ton overhead cranes are suitable for various light and medium-duty applications. They deliver high efficiency, safety, economy, and easy maintenance. With multiple configurations and flexible adaptation, HSCRANE helps customers achieve maximum lifting efficiency within limited space and budget. Whether for new workshops, production line expansion, or plant renovation, a 3-ton overhead crane is a key device for improving handling efficiency and production rhythm.

Looking for the best 3-ton overhead crane for your application? Contact the HSCRANE engineering team for a free selection plan and customized quotation!

Q1: What are the typical span and lifting height of a 3-ton overhead crane?

A: The span can be customized from 6–30 meters. The lifting height is designed based on building headroom, typically 6–12 meters. Low-headroom models offer greater effective lifting height.

Q2: Is a 3-ton overhead crane suitable for continuous operation?

A: Yes. We recommend European-type designs or A5/FEM 2m models for long-term, high-frequency lifting.

Q3: Can the crane be installed in a height-restricted workshop?

A: Yes. Low-headroom, underslung, or offset-trolley models can adapt to narrow spaces or old factory upgrades.

Q4: Can the crane be equipped with wireless remote control?

A: Yes. Common control options include:

- Wired control

- Wireless remote control

- Dual-mode control (wired + remote)

Q5: Does HSCRANE provide on-site installation and commissioning services?

A: Yes. We support global installation, commissioning, training, and long-term maintenance with spare parts supply.

Q6: How can I confirm the right model for my 3-ton overhead crane?

A: HSCRANE engineers will select the proper model based on your workshop size, lifting frequency, travel path, load weight, and lifting height.

Interested in overhead cranes? You may also find this useful: Bridge Crane Selection Guide: How to Pick the Best Crane for Your Workshop

Recent Post