Blog

- Home

- Blog

Deck Crane: An Efficient Solution for Shipboard Cargo Handling

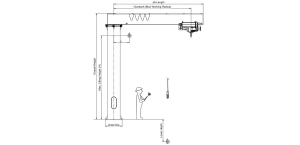

The Deck Crane, also known as a ship-mounted jib crane, is installed on vessel decks for cargo handling, material transfer, or offshore operations.Unlike traditional cranes relying on steel rope systems, it uses dual hydraulic cylinders to move ropes across pulleys for lifting.With a compact structure, larger deck availability, easy operation, and high efficiency, it enables fast loading/unloading without preparation, covering a wide range of applications.

Core Structure

- Boom: Telescopic or fixed, determines working radius.

- Base: Support structure with slewing bearing for rotation.

- Drive System: Hydraulic power pack, motor, or diesel engine.

- Control System: Joystick, remote control, or automated system.

- Safety Devices: Limit switches, overload protection, and emergency brakes.

Product Features

- Can lift loads into the water or onto the dock.

- Equipped with auto-diagnostic wave compensation to ensure stability in rough seas.

- Optional boom types: fixed, telescopic, or knuckle.

- Slewing up to 355° for maximum flexibility.

- Available in non-extendable or single telescopic boom designs.Single telescopic booms offer wider range with less deck space.

- High-performance synthetic rope as standard for ease of use.

- Optional galvanized steel rope for extra strength.

- Additional safety arm lights can be installed.

- Wireless remote control enhances flexibility and safety.

Technical Standards

Designed in compliance with CCS (China Classification Society) rules.Follows GB/T 3811-2008 Crane Design Code.

Product Specifications

|

Load Capacity (t) |

Outreach (m) |

Max. Lifting Height (m) |

Duty Class |

|

1 |

3–6 |

3–8 |

A3 / A5 |

|

2 |

5–35 |

3–25 |

A3 / A5 |

|

3 |

5–35 |

3–25 |

A3 / A5 |

|

5 |

5–35 |

3–25 |

A3 / A5 |

|

8 |

5–35 |

3–25 |

A3 / A5 |

|

10 |

5–35 |

3–25 |

A3 / A5 |

|

12 |

5–35 |

3–25 |

A3 / A5 |

|

Power: 380-460V, 50/60Hz, three-phase FEM Class: A3 and A5 are standard |

|||

Product Advantages

- Lightweight body with low procurement cost.

- Compact design saves deck space.

- Up to 70% reduction in maintenance cost.

- Low labor demand – single operator control.

- Service life extended by 30% compared to traditional electric cranes.

- Fully compliant with ISO, LY2, LY3, and SOLAS standards.

- Premium finishing: polished, painted, and coated with yacht-grade paint.

- Dual-speed or proportional remote control available.

- Rescue cranes usually include rope control; cargo cranes may add optional rope control.

Application Scenarios

- Cargo Vessels: Container, bulk cargo, and heavy equipment handling.

- Offshore Engineering Ships: Deployment of ROVs, pipelines, and repair tools.

- Rescue & Research Vessels: Launch/recovery of boats and sampling equipment.

- Naval Ships: Transport of supplies and weapons.

HSCRANE Commitment

To meet market demand, HSCRANE has invested in a modern manufacturing base with advanced production technology.Our product portfolio includes overhead cranes, gantry cranes, electric hoists, transfer carts, and bridge launching girders, all fully compliant with FEM standards.In recent years, we introduced two flagship innovations: rubber-tired cranes and mobile lifts, delivering efficient, reliable, and versatile lifting solutions.

Recent Post