Blog

- Home

- Blog

Main Factors Affecting the Lifting Capacity of Overhead Crane

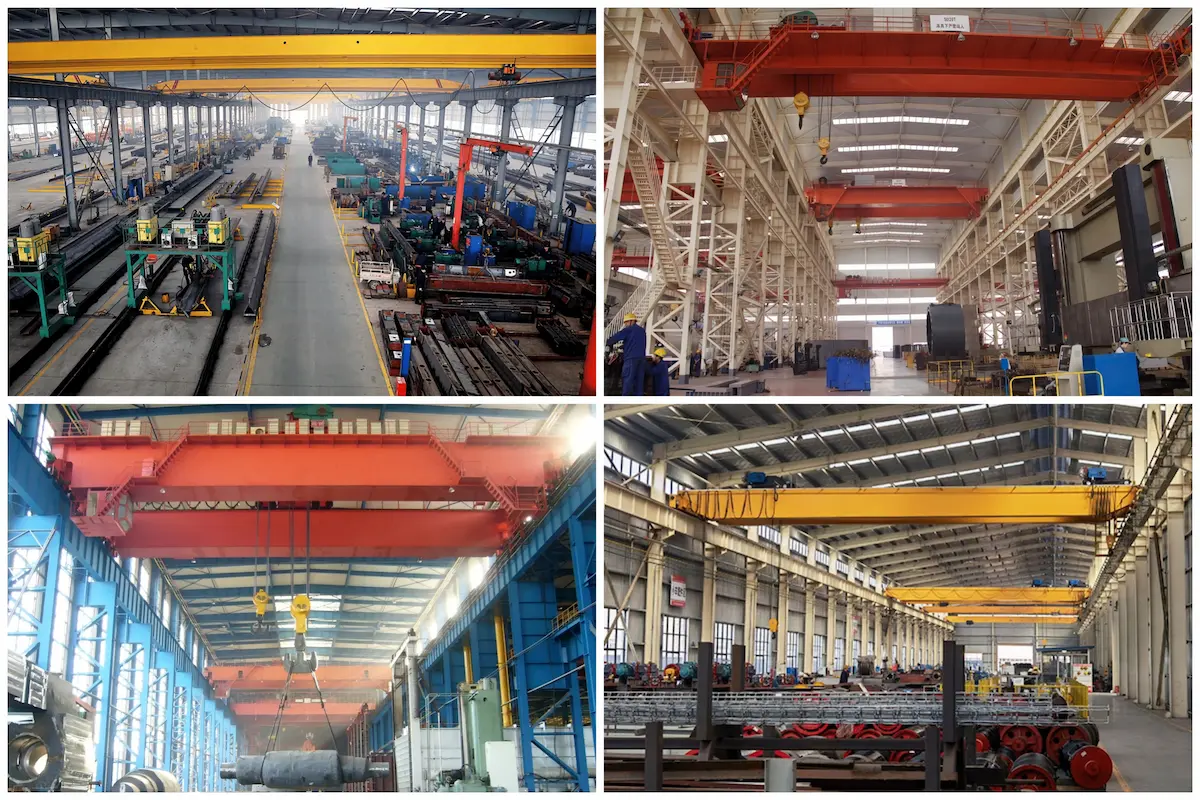

As one of the most widely used lifting devices, overhead crane serve industrial manufacturing, warehousing logistics, steel fabrication, and heavy assembly industries. Lifting capacity is a key parameter customers focus on during crane selection and purchasing. In practice, overhead crane lifting capacity is not determined by a single factor. It is influenced by multiple structural, technical, and operational conditions together. This article analyzes key factors affecting overhead crane lifting capacity from several important dimensions. It helps customers make more scientific equipment selection decisions.

Main Girder Structure and Material Strength

The main girder is the core load-bearing component of an overhead crane. Its structural design and material properties directly determine the maximum load capacity.

●Structural type: Common designs include box girders, I-beams, and combined girders, while box girders offer higher rigidity for heavy lifting.

●Steel grade: High-strength low-alloy steel increases load capacity while reducing self-weight compared with carbon steel.

●Welding quality and manufacturing accuracy: High-quality welding and strict tolerance control improve load distribution and reduce stress concentration.

Hoisting Mechanism and Electric Hoist Configuration

The hoisting mechanism is the key system responsible for lifting operations. Its performance directly affects crane lifting capacity.

●The rated load of electric hoists or winch systems must match the overall crane design capacity.

●Wire rope diameter and reeving design affect actual lifting capacity and safety factors.

●Gearbox, brake, and coupling performance influence stability and safety under heavy load conditions.

Span and Lifting Height Design

Overhead crane span and lifting height are not always better when increased. These parameters significantly affect structural stress and load performance.

●Larger spans increase main girder deflection and stress, requiring higher structural strength.

●Greater lifting height increases wire rope length and hoisting system load, affecting rated lifting capacity.

●Therefore, reasonable control of span and lifting height improves equipment economy and operational safety.

Working Class and Duty Frequency

Overhead crane design usually follows ISO, FEM, or CMAA duty classifications.

●High duty classes such as A6 or A7 suit frequent and heavy-duty operating conditions.

●Long-term high-frequency operation requires higher fatigue strength and component durability.

●Under the same rated capacity, higher duty class cranes provide better reliability and longer service life.

Travel Mechanism and Overall Stability

During heavy lifting operations, crane traveling stability must not be ignored.

●End carriage and wheel assembly design affect overall traveling smoothness.

●Rail accuracy and installation quality indirectly influence safe lifting capacity.

●Anti-sway systems and limit protection devices ensure safe operation under heavy load conditions.

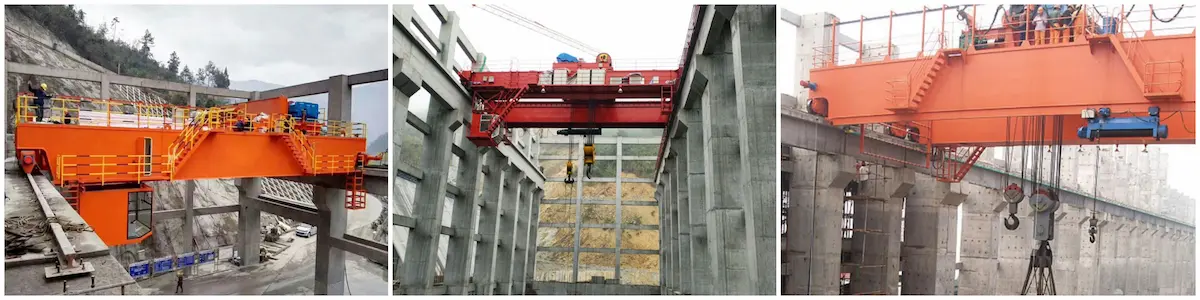

Operating Environment and Working Conditions

Environmental factors are important external conditions affecting crane lifting capacity, including:

●High-temperature, low-temperature, or corrosive operating environments.

●Outdoor wind load, humidity, and dust exposure conditions.

●Explosion-proof, corrosion-resistant, or dust-proof requirements under special working conditions.

In complex environments, cranes often require special designs or reduced rated loads for long-term stable operation.

In summary, overhead crane lifting capacity results from combined effects of structure, core components, duty class, and operating environment. During selection, users should consider more than rated lifting capacity alone. Specific working conditions, usage frequency, and future expansion requirements should be fully evaluated. As an experienced crane manufacturer with customization capabilities, HSCRANE delivers safe, efficient, and long-term overhead crane solutions.

This document is for reference only. Specific operations must strictly comply with local laws and regulations and equipment manuals.

Recent Post