Blog

- Home

- Blog

Key Factors Affecting Overhead Crane Lifting Capacity and Working Load

In industrial production and heavy material handling, the overhead crane plays a critical role in lifting operations. Its lifting capacity and working load level are directly related to operational safety, stability, and overall production efficiency. During equipment selection, focusing solely on the rated lifting capacity while overlooking factors such as structural design, hoisting system configuration, duty class, and actual operating conditions can lead to incorrect capacity assessment. In practice, the lifting capacity of an overhead crane is not determined by a single parameter, but by the combined effect of multiple key technical factors. A thorough understanding of these core elements helps users reasonably configure working loads under different operating conditions, avoid overloading risks, and extend the service life of the equipment.

Basic Concepts of Lifting Capacity and Working Load of Overhead Cranes

In the design, selection, and practical application of an overhead crane, lifting capacity and working load are two fundamental concepts that are often confused. Clearly understanding their definitions and differences is essential to ensuring safe operation and maximizing equipment value.

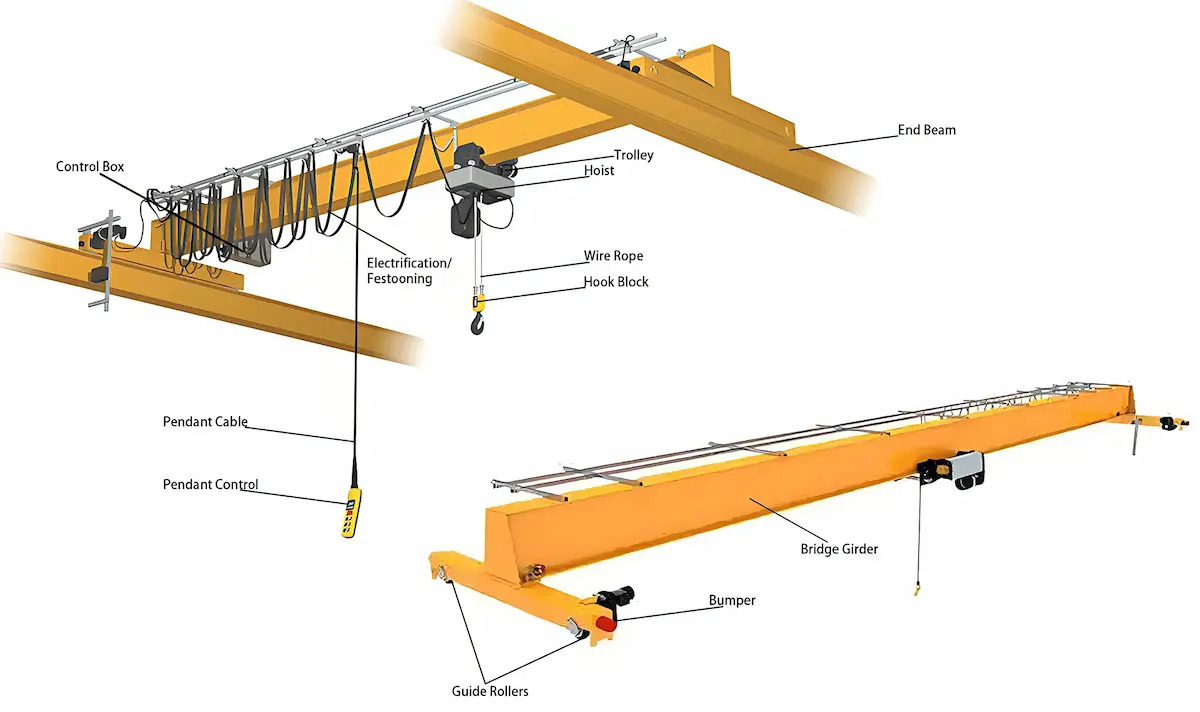

Definition of Lifting Capacity and Explanation of Rated Lifting Capacity

Lifting capacity refers to the maximum weight that an overhead crane can safely lift under specified design standards and defined operating conditions. In engineering practice, lifting capacity is typically expressed as the rated lifting capacity.

The rated lifting capacity means:

▴The crane operates under standard conditions

▴At the specified lifting height, lifting speed, and duty class

▴The maximum load that can be lifted safely and continuously over the long term

It is important to note that the rated lifting capacity does not include:

▴The self-weight of the hook block

▴The weight of wire ropes and pulley blocks

▴The weight of special lifting devices (such as grabs, electromagnetic lifters, etc.)

These additional weights are directly included in the actual load acting on the crane during operation and therefore affect the effective lifting capacity.

Difference Between Working Load and Rated Lifting Capacity

Working load refers to the total load borne by the structure and mechanisms of an overhead crane during actual operation, which is much broader than the weight of the lifted object alone.

The working load typically includes:

▴The self-weight of lifting devices, hooks, and wire ropes

▴Dynamic loads generated during lifting, braking, and acceleration

▴Adverse operating factors such as eccentric loading and impact loads

Compared with the rated lifting capacity, the working load has the following characteristics:

▴Dynamic variability: it changes with operating speed, handling methods, and working conditions

▴High comprehensiveness: it affects not only the hoisting mechanism, but also the main girder, end carriages, and traveling mechanisms

▴Higher safety relevance: it is the key criterion for determining whether the crane is operating under overload conditions

Therefore, even if the lifted load does not exceed the rated lifting capacity, the actual working load may still surpass the allowable design limits.

Why It Is Necessary to Distinguish Between “Theoretical Lifting Capacity” and “Actual Working Load”

In engineering applications, theoretical lifting capacity usually refers to the rated lifting capacity calculated based on design parameters and standard operating conditions. Actual working load, however, reflects the real load conditions acting on the crane during practical operation.

▴Avoid the risk of “nominally not overloaded, but actually overloaded”: Ignoring dynamic loads, the weight of lifting devices, and impact factors may result in the crane operating within the rated lifting capacity while the structure or mechanisms are already overloaded in reality.

▴Ensure structural safety and service life: Long-term operation under high working loads accelerates fatigue of the main girders, wear of wire ropes, and aging of critical components, significantly shortening the service life of the overhead crane.

▴Ensure sustainable lifting performance under complex operating conditions: High-frequency operation, heavy loads, or special conditions (such as eccentric loading or rapid lifting) impose higher demands on actual working load. Properly distinguishing the two helps achieve scientific equipment selection and accurate matching with operating conditions.

▴Comply with safety codes and industry standards: Most crane design codes and safety standards use working load, rather than a single rated lifting capacity value, as a key basis for safety verification.

Key Factors Affecting the Lifting Capacity and Working Load of an Overhead Crane

The lifting capacity of an overhead crane is not determined by a single parameter. Instead, it is the result of the combined effects of structural design, mechanical configuration, duty class, and control systems. The following analysis examines these factors across five critical dimensions:

|

Category |

Key Factor |

Technical Explanation |

Impact on Lifting Capacity |

Impact on Working Load |

Selection & Application Guidance |

| Main Girder Structure & Material Strength | Main girder type | Box girders offer high stiffness and strong bending/torsional resistance; truss girders are lightweight but have limited load capacity | Determines the theoretical upper limit of lifting capacity | Affects long-term stable load-bearing ability | Box girders are preferred for medium-to-heavy loads and high-frequency operation |

| Steel grade | High-strength low-alloy steel increases load capacity while reducing self-weight | Improves design lifting capacity | Reduces structural fatigue risk | High-grade structural steel is recommended for heavy-duty conditions | |

| Welding quality | Weld quality affects stress concentration and overall strength | Poor welding limits lifting capacity | Welding defects reduce allowable working load | Pay close attention to welding standards and NDT inspections | |

| Girder deflection control | Excessive deflection affects traveling mechanisms and stability | Excessive deflection requires derating | Actual working load must be reduced | Deflection control is often more critical than strength | |

| Hoisting Mechanism Configuration | Hoisting motor power | Determines lifting capability and efficiency | Insufficient power prevents full rated capacity | High risk of overload under heavy load | Motor selection must match maximum operating conditions |

| Gearbox matching | Gear ratio affects lifting speed and torque | Proper matching releases full lifting capacity | Poor matching increases dynamic loads | Heavy-load and high-speed applications require differentiated configurations | |

| Drum diameter | Larger drums distribute wire rope stress more evenly | Indirectly increases usable lifting capacity | Reduces wire rope fatigue load | Heavy-duty cranes should use larger drum diameters | |

| Reeving ratio | Higher reeving shares load across multiple ropes | Improves safe lifting capacity | Raises safe working load limit | High reeving ratios are recommended for heavy and high-frequency operation | |

| Braking system | Braking torque reliability determines safety under load | Inadequate braking limits lifting capacity | Prevents loss of control or impact under heavy load | High-duty cranes must use high-performance brakes | |

| Duty Class & Usage Frequency | Duty class | Reflects load magnitude and usage frequency | Determines the design lifting capacity level | Determines allowable continuous load | High-frequency heavy-duty use requires a higher duty class |

| Usage frequency | Number of lifts and operating duration | High frequency requires higher design margins | Actual working load should be reduced | Low-duty cranes should not operate continuously at full load | |

| Load spectrum | Ratio of light to heavy loads | Influences fatigue design | Determines service life and safety margin | High full-load ratios require derating | |

| Traveling Mechanisms & Operation | Bridge traveling mechanism | Affects overall force distribution and wheel loads | Uneven forces limit lifting capacity | Can easily cause eccentric loading | Ensure synchronized driving and braking |

| Trolley traveling mechanism | Directly bears hoisting load | Insufficient stability limits rated capacity | Eccentric load amplifies actual working load | Reinforce trolley rigidity for heavy-duty use | |

| Rail accuracy | Gauge and straightness affect operation | Poor accuracy reduces safe lifting capacity | Increases dynamic and impact loads | Cranes on poor rails should operate at reduced load | |

| Overall crane rigidity | Coordination between main and end girders | Higher rigidity allows full lifting capacity utilization | Improves stability under heavy load | Heavy-duty cranes require overall structural reinforcement | |

| Control Systems & Safety Devices | Load limiter | Real-time detection of lifting load | Prevents exceeding design lifting capacity | Effectively limits working load | Essential for heavy-duty overhead cranes |

| Variable frequency control | Smooth lifting, braking, and traveling | Reduces dynamic load, increasing usable capacity | Minimizes instantaneous load impact | Strongly recommended for high-frequency and precision operations | |

| Intelligent monitoring systems | Records load and operating data | Improves controllability of lifting capacity | Enables long-term working load management | Supports predictive maintenance and safety management |

Impact of Operating Conditions on the Working Load of an Overhead Crane

In real-world applications of an overhead crane, even when the rated lifting capacity and structural design are identical, the actual working load level and safe lifting capacity can vary significantly under different operating conditions. Environmental factors, operating methods, and external load influences all directly affect the crane’s ability to withstand loads.

Differences Between Indoor and Outdoor Operating Conditions

Characteristics of Indoor Conditions

▴Stable environment with minimal wind load influence

▴Temperature and humidity variations are relatively controllable

▴Higher accuracy and stability of runway rails

Under indoor conditions, an overhead crane can usually fully utilize its designed lifting capacity, with the working load close to the rated lifting capacity. This makes it suitable for high-frequency and precision lifting operations.

Characteristics of Outdoor Conditions

▴Exposure to wind loads, temperature differences, rain, and snow

▴Steel structures are subject to thermal expansion and contraction

▴Runway rails are more prone to settlement or misalignment

In outdoor applications, increased external uncertainties require the actual working load to be appropriately reduced based on environmental conditions to ensure structural integrity and operational safety.

Load Adjustments in High-Temperature, Dusty, and Corrosive Environments

Impact of High-Temperature Environments

▴High temperatures reduce the yield strength of steel

▴Efficiency of motors and brakes decreases

▴Lubrication system performance degrades

In high-temperature applications such as metallurgy and foundries, the allowable working load of an overhead crane must be adjusted. This is typically achieved by increasing structural design margins or reducing the actual lifting load.

Impact of Dusty Environments

▴Dust can enter transmission and braking systems

▴Increases running resistance and component wear

▴Affects braking response speed

Under long-term dusty conditions, although the nominal lifting capacity remains unchanged, the actual safe working load capability decreases. Enhanced sealing and more frequent maintenance are required.

Impact of Corrosive Environments

▴Corrosion reduces effective structural cross-sections

▴Safety of welds and connection points deteriorates

▴Long-term operation involves hidden load-bearing risks

In corrosive environments such as chemical plants or coastal areas, the working load must be conservatively controlled, and structural load-bearing capacity should be regularly assessed.

Effects of Wind Load, Eccentric Load, and Impact Load on Lifting Capacity

Wind Load Effects (Primarily for Outdoor Cranes)

▴Wind load generates lateral forces on the bridge structure and the lifted load

▴Amplifies forces acting on traveling mechanisms and the structure

▴Lifting operations must be restricted under strong wind conditions

When wind loads are present, the actual usable lifting capacity of an overhead crane is significantly reduced.

Impact of Eccentric Loads on Working Load

▴Offset load centers cause uneven force distribution

▴Increase stress on main girders, wire ropes, and wheel loads

▴Lifting capacity must be significantly reduced under eccentric loading

Eccentric loading is one of the most common hidden risks in real operating conditions and, in severe cases, can cause the working load to exceed the design limits.

Impact of Shock Loads on Lifting Capacity

▴Rapid lifting, sudden stops, or emergency braking generate shock loads

▴Shock loads can momentarily exceed static loads by 1.2–1.5 times

▴Cause additional fatigue damage to structures and mechanisms

Controlling shock loads is a critical prerequisite for safely utilizing lifting capacity.

Principles for Proper Matching of Lifting Capacity and Working Load in Overhead Cranes

▴Avoiding “overestimated lifting capacity” during selection: The lifting capacity of an overhead crane must be reasonably matched to the actual working load. Selection should not rely solely on rated lifting capacity. Ignoring operating conditions, usage frequency, and load variations can result in cranes that appear sufficient on paper but operate near critical load limits in practice, increasing safety risks to structures and mechanisms.

▴Importance of safety margins: Safety factors are not only required to meet standards but also to address uncertainties such as shock loads, operational deviations, and variations in material performance. Insufficient safety margins accelerate fatigue and wear of critical components, reducing overall reliability.

▴Relationship between lifting capacity and long-term stable operation: Proper lifting capacity configuration allows the crane to operate within a stable working load range under most conditions, meeting production needs while reducing failure rates and maintenance costs. This achieves a balanced combination of safety, stability, and economic efficiency.

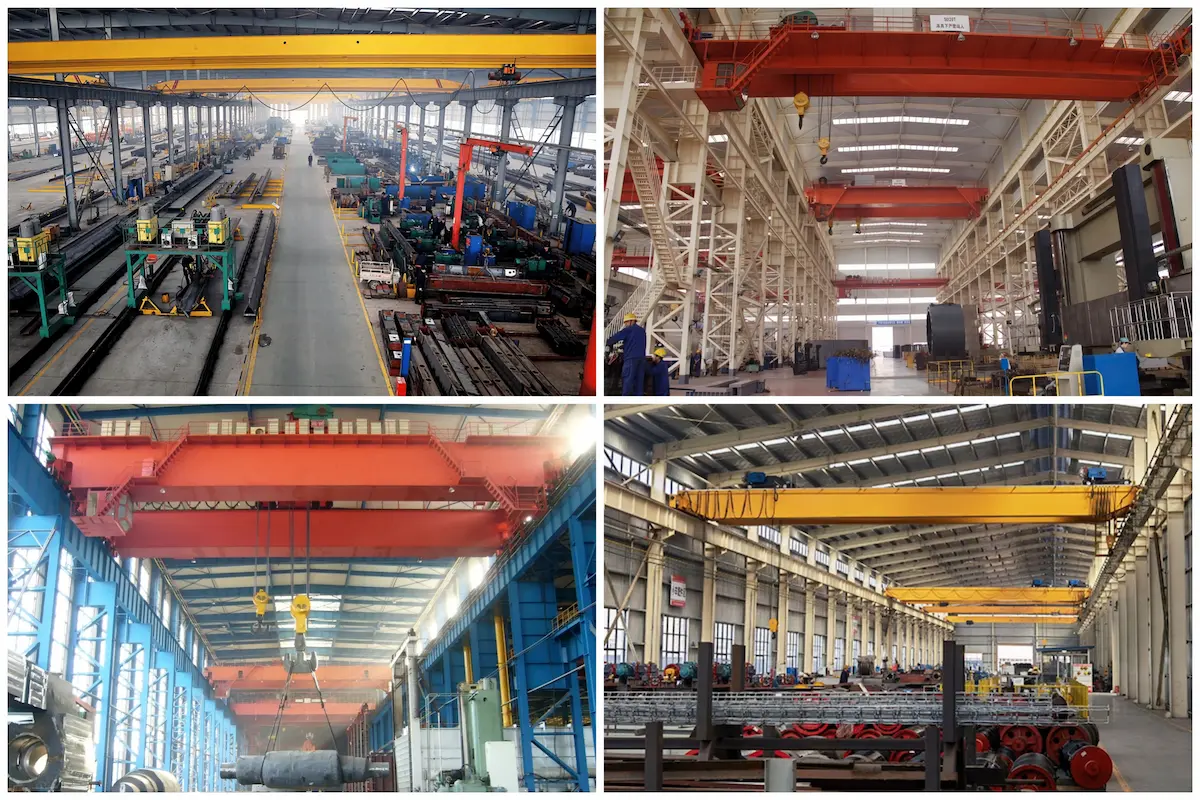

HSCRANE’s Strengths in Overhead Crane Lifting Capacity Performance

▴High-standard structural design ensuring true lifting capacity: HSCRANE overhead cranes use high-strength steel and optimized box-type main girder designs. Deflection control is maintained at levels significantly stricter than common industry standards, ensuring that the rated lifting capacity is not a short-term figure, but a sustainable and reliable capability under long-term loading and complex conditions.

▴Precisely matched hoisting systems for full utilization of working load capacity: Hoisting mechanisms, motors, gearboxes, and wire rope systems are scientifically selected based on load characteristics and usage frequency. This effectively reduces shock loads during lifting and improves utilization of the safe working load, resulting in smoother and more efficient operation.

▴Multiple duty class options for heavy-duty and high-frequency applications: HSCRANE provides overhead crane solutions covering duty classes from A3 to A8, making them especially suitable for steel plants, heavy manufacturing, and continuous operation environments.

▴Intelligent safety systems for controlled lifting capacity utilization: By integrating high-precision load limiters, variable frequency drives, and real-time load monitoring systems, lifting capacity is always released in a controlled manner. This effectively prevents overload operation and ensures long-term, safe, and stable crane performance.

When selecting an overhead crane, a deep understanding of the core factors influencing lifting capacity and working load is essential to ensure safe operation, stable performance, and long-term value. Only by relying on solid engineering principles and fully integrating actual operating conditions into systematic design and selection can lifting equipment continuously deliver real, reliable lifting capacity in complex and variable industrial environments—meeting modern industry’s demands for heavy-duty, efficient, and safe lifting.

Contact HSCRANE to let our professional team tailor the optimal overhead crane solution based on your actual operating conditions.

To learn more about overhead crane selection under different operating conditions, click to view Bridge Crane Selection Guide: How to Pick the Best Crane for Your Workshop, and gain reference insights for safer and more efficient lifting configurations.

Recent Post