Blog

- Home

- Blog

Crane Applications in Mining Development: Improving Operational Efficiency and Safety

In the mineral development industry, lifting equipment runs through the entire production process and serves as a fundamental asset for ensuring efficient and continuous mine operations. From the hoisting of large components during ore extraction, to material transfer in ore transportation, and further to beneficiation, smelting, and subsequent equipment inspection and maintenance, cranes consistently undertake critical material handling and heavy-duty operations. Their performance and reliability directly affect the production rhythm and overall operational efficiency of mining sites. Compared with general industrial applications, mineral development places far more stringent demands on lifting equipment. Ores are characterized by high density and heavy unit weights, requiring cranes to operate under high-load or even full-load conditions for extended periods. Mining operations are typically continuous, demanding long-term stable performance from equipment. At the same time, harsh environments—including heavy dust, high humidity, strong corrosive media, and extreme high or low temperatures—pose severe challenges to crane structural strength, electrical systems, and protective performance.

Under such conditions, safety and stability become non-negotiable core requirements for mining lifting equipment. Any failure of a lifting system can lead not only to production interruptions and economic losses, but also to serious safety incidents. Therefore, selecting cranes that can meet the special operating conditions of mineral development, while offering high reliability and comprehensive safety protection, is a critical prerequisite for modern mines to achieve safe production and efficient operation.

Main Application Scenarios of Cranes in Mineral Development

Hoisting and Transfer of Run-of-Mine Ore and Minerals

At the early stages of mineral development, the hoisting and transfer of raw ore and minerals represent the most basic and most frequent operations. Cranes are widely used to move ore from extraction points to transfer areas, storage bins, or transportation systems such as mine cars and belt conveyors.

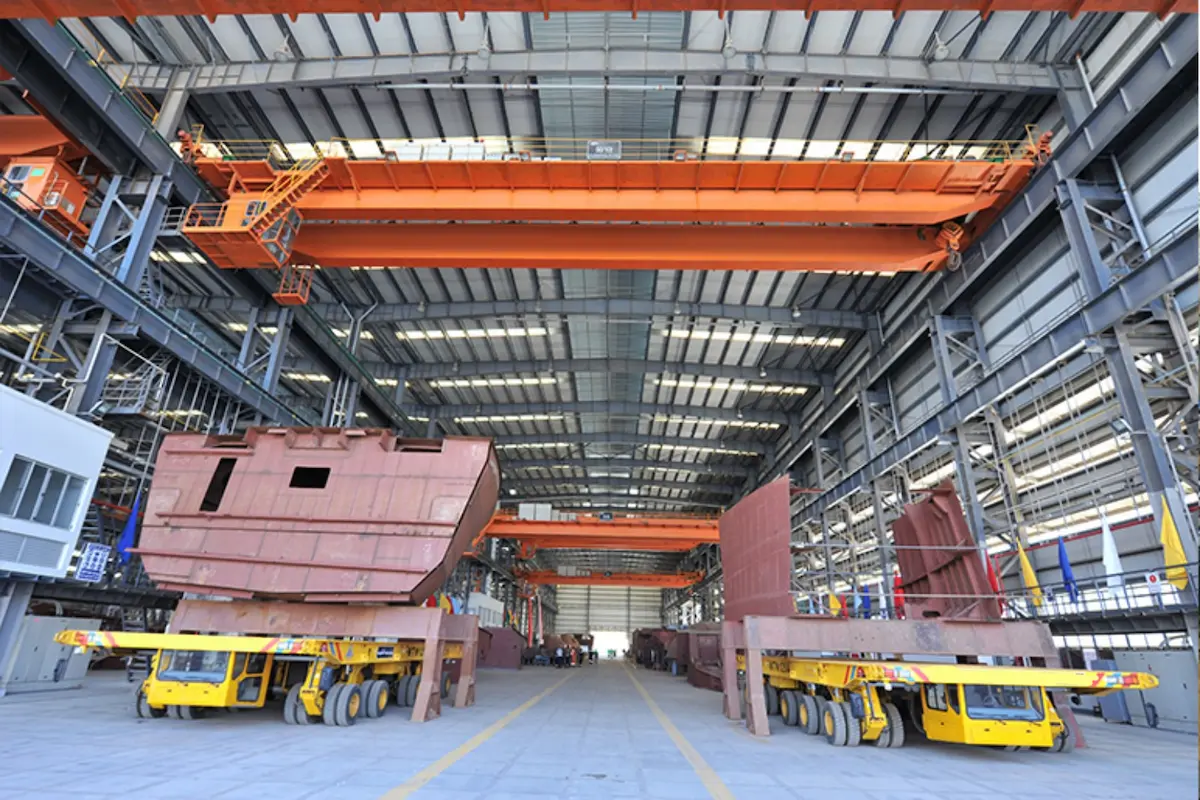

These operations are typically characterized by high single-lift loads, frequent duty cycles, and long operating hours, placing extremely high requirements on crane load capacity, operational stability, and fatigue resistance. Overhead cranes and Gantry cranes, with their large lifting capacities and extensive coverage, significantly improve ore transfer efficiency, reduce manual intervention, and ensure continuous production.

Material Handling in Crushing, Beneficiation, and Processing Workshops

In crushing, screening, beneficiation, and subsequent processing workshops, cranes are mainly used for the internal handling of ore, semi-finished products, and related materials. Although these areas are relatively compact, operating conditions are complex and often involve heavy dust, high humidity, and corrosive environments.

In this stage, cranes not only perform material lifting tasks but also directly influence production tempo and process coordination within the workshop. Stable operation, precise positioning, and well-designed protective features help reduce equipment wear and unplanned downtime, thereby improving overall processing efficiency.

Installation and Maintenance of Heavy Equipment and Key Components

During mineral development, the installation, replacement, and maintenance of large crushers, ball mills, hoists, and other critical equipment rely heavily on cranes. Such operations are generally low-frequency but high-risk, placing extremely strict demands on crane safety and reliability.

For equipment installation and maintenance, cranes must provide smooth lifting, precise control, and multiple safety protection functions to ensure heavy components are handled in a controlled and secure manner. This helps reduce maintenance risks and minimize equipment downtime.

Construction of Mining Infrastructure and Auxiliary Systems

During mine construction and expansion phases, cranes are also widely used for infrastructure and auxiliary system projects, including the installation of plant steel structures, construction of storage bins, and installation of power and piping systems. These stages involve diverse tasks and long construction cycles, requiring high adaptability and versatility from lifting equipment.

Through the appropriate configuration of overhead cranes, Gantry cranes, or mobile lifting equipment, construction efficiency can be significantly improved, project quality ensured, and a solid foundation established for the mine’s long-term stable operation.

Key Considerations for Crane Selection Under Different Mining Operating Conditions

Differences Between Open-Pit and Underground Mining Environments

Mineral development can generally be divided into open-pit mining and underground mining based on operating environments. These two scenarios present significantly different requirements for crane selection.

|

Comparison Aspect |

Open-Pit Mine |

Underground Mine |

| Operating Space | Open and expansive, with large working areas | Space-constrained, with relatively concentrated working zones |

| Environmental Characteristics | Long-term exposure to outdoor conditions | Enclosed or semi-enclosed environments |

| Major Environmental Impacts | Wind loads, rain and snow, dust, large day–night and seasonal temperature variations | High humidity, concentrated dust, complex ventilation conditions |

| Lifting Capacity Demand | Typically high, to handle heavy ore and large components | More controllable, with greater emphasis on precision and stability |

| Span Requirements | Large spans and wide coverage to reduce equipment relocation | Smaller spans, emphasizing compact layouts |

| Structural Strength Requirements | High structural strength with strong wind resistance and fatigue resistance | Compact structure with high stability to suit confined spaces |

| Protection and Anti-Corrosion Requirements | High requirements for corrosion resistance, waterproofing, and dust protection for long-term outdoor operation | Emphasis on moisture resistance, dust protection, and sealed electrical systems |

| Safety Control Focus | Wind resistance and prevention of environment-induced failures | Precise control and multiple safety protections in personnel-intensive areas |

| Typical Lifting Equipment | Gantry crane, outdoor-type overhead crane | Low-headroom overhead crane, electric hoists, winches |

Common Types of Lifting Equipment in Mining

|

Equipment Type |

Main Application Scenarios |

Typical Operating Characteristics |

Selection Advantages |

| Overhead crane | Beneficiation plants, crushing workshops, processing workshops, maintenance bays | Frequent operations, heavy loads, continuous duty | High lifting capacity, stable operation, precise positioning; suitable for medium to high duty classes |

| Gantry crane | Open-pit mining areas, ore stockyards, raw material transfer zones, component handling areas | Outdoor operation, large spans, open environments | Wide coverage, strong adaptability to outdoor conditions, minimal dependence on buildings |

| Electric hoist | Underground mining areas, internal workshops, auxiliary lifting points | Space-limited, relatively small loads | Compact structure, flexible installation; suitable for localized or auxiliary lifting |

| Winch | Equipment installation, maintenance, special lifting conditions | Complex lifting paths, high control requirements | Strong traction capability; suitable for non-standard or special lifting operations |

General selection guidance:

▴For high-load, continuous production scenarios, prioritize overhead cranes or Gantry cranes.

▴For space-constrained or auxiliary operations, electric hoists and winches offer greater flexibility.

▴In practical projects, a combination of different lifting equipment is often adopted to meet diverse operational needs.

Principles for Selecting Lifting Capacity, Span, Duty Class, and Protection Rating

Lifting capacity: The rated capacity should meet maximum lifting requirements while accounting for high ore density and impact loads. It is recommended to maintain a reasonable safety margin above nominal demand to adapt to complex mining conditions.

Span: Span selection should align with mine layout or plant configuration. Open-pit mines and stockyards typically require larger spans to reduce equipment relocation, while underground mines and workshops prioritize compact arrangements and efficient space utilization.

Duty class: Mining cranes generally fall into medium to high duty classes (such as A5–A7 or higher) to accommodate frequent lifting and long operating hours. Proper duty class selection helps extend service life and reduce failure rates.

Protection rating: Given common mining conditions—dust, high humidity, corrosive gases—special attention should be paid to protection ratings of electrical systems and critical components, including dustproof, waterproof, anti-corrosion, and explosion-proof designs to ensure long-term stable operation under harsh conditions.

Crane Technology Essentials for Improving Mining Operational Efficiency

In mineral development, cranes do more than perform lifting tasks—they directly influence overall mining productivity. Through targeted technical configurations and system optimization, lifting equipment can significantly enhance operating tempo and reliability under high-load, continuous-duty conditions.

Impact of Efficient Hoisting and Precise Positioning on Production Rhythm

Hoisting speed and system responsiveness determine the completion time of each lifting cycle. In high-frequency mining operations, efficient hoisting systems shorten cycle times and increase throughput per unit time. At the same time, precise positioning and anti-sway control technologies reduce repeated adjustments and manual intervention, enabling smoother ore handling and equipment installation, and ensuring continuity and stability across production processes.

Application of Automation and Electrical Control Systems in Mining

Modern mining cranes increasingly integrate automation and intelligent electrical control systems, such as variable frequency drives (VFDs), synchronized control, and condition monitoring. These technologies enable smooth hoisting, accurate motion control, and coordinated multi-axis operation, reducing human error and improving operational consistency. In complex or hazardous conditions, automation further minimizes direct human involvement, enhancing both productivity and operational safety.

Design Approaches to Reduce Downtime and Maintenance Costs

Given the continuous operating nature of mining, crane design should prioritize structural durability and the reliability of critical components. By optimizing structural design, selecting long-life components, and enhancing electrical system protection, failure frequency can be significantly reduced. In addition, maintenance-friendly modular designs and condition monitoring support planned maintenance, lower the risk of unplanned downtime, and improve mining efficiency while controlling lifecycle operating costs.

Safety Requirements in Mineral Development and Crane Solutions

Analysis of Common Safety Risks in Mining Operations

Mining lifting operations are typically characterized by heavy loads, continuous duty, and harsh environmental conditions. Common safety risks include:

Overloading

Load sway during lifting operations

Operating errors caused by limited visibility

Performance degradation due to dust, high humidity, or corrosive media

In addition, during equipment installation and maintenance, risks are concentrated around the lifting of heavy components. Improper control can easily result in equipment damage or personal injury.

Crane Technologies for Overload Protection, Anti-Sway, and Loss-of-Control Prevention

To address these risks, modern mining cranes are typically equipped with multiple safety protection systems:

Overload protection devices: Monitor lifting loads in real time and trigger alarms or restrict movements when rated capacity is exceeded, preventing damage to structures and mechanisms.

Anti-sway and precision control technologies: Using VFD control and synchronized motion, these systems effectively reduce load sway and improve lifting stability.

Redundant braking systems, emergency stop functions, and limit switches: Prevent uncontrolled movements under abnormal conditions and enhance overall operational safety.

Importance of Compliance with International and Regional Standards

Mineral development projects—especially cross-border or export-oriented projects—are subject to increasingly stringent compliance requirements. Conformance with ISO, FEM, EN, and relevant national or regional standards is not only a prerequisite for project acceptance and commissioning, but also a clear indicator of reliability in terms of structural strength, safety factors, and electrical protection. Selecting crane solutions that comply with international and regional standards helps reduce operational risks and improves the long-term safety and sustainability of mining projects.

HSCRANE’s Advantages in Mining Applications

Customized design capability: HSCRANE provides purpose-built designs tailored to mining-specific conditions such as high dust levels, high humidity, and heavy loads, ensuring stable and reliable crane operation under harsh environments.

Stable and reliable structures and key components: By adopting high-strength structures and premium critical components, HSCRANE cranes support long-term, high-frequency operation, reducing failure rates and improving production continuity and efficiency.

Extensive mining project experience: HSCRANE has delivered numerous mining projects across steel, metallic mining, and non-metallic mining sectors, enabling optimized solutions for different ore types and operating conditions.

Compliance with international standards: All products are designed in strict accordance with ISO, FEM, and EN standards, balancing safety and reliability while meeting acceptance requirements for domestic and international mining projects, including exports.

Comprehensive technical support and service system: HSCRANE offers end-to-end support—from solution design and equipment manufacturing to installation, commissioning, and after-sales service—ensuring professional assistance throughout the entire equipment lifecycle.

In modern mineral development, lifting equipment is not merely a material handling tool—it is a critical foundation for efficient and safe production. Choosing professional crane solutions enables mining operations to address complex conditions, improve efficiency, reduce safety risks, and achieve a balance between productivity and safety. Efficient hoisting, precise control, robust and reliable structures, and internationally compliant safety protection are key factors in ensuring safe and efficient mining operations.

At the same time, a comprehensive technical support and service system provides full protection during equipment selection, installation, commissioning, and long-term maintenance, helping mining enterprises reduce operational risks and costs.

With extensive industry experience, reliable product performance, and a complete technical service system, HSCRANE continues to provide comprehensive support for mining projects worldwide—helping mining companies achieve stable, efficient operations. Contact HSCRANE today to receive a customized crane solution for your mining project and make your operations safer and more efficient.

To learn more about lifting equipment applications in the concrete industry, click to explore:

Customized Lifting Solutions for the Precast Concrete Industry: Efficient, Safe, and Cost-Effective Handling, and gain access to more targeted configurations and professional technical support.

Recent Post