Blog

- Home

- Blog

EOT Double Girder Crane: Structure, Features, and Working Principle

In the realm of industrial material handling, the EOT double girder crane stands out for its exceptional performance and efficiency.

This electric overhead traveling crane, designed for precise horizontal and vertical material movement, is a powerhouse in large-scale environments.

Widely used in factories, workshops, steel mills, machinery manufacturing plants, and assembly lines, it boosts productivity while reducing manual labor.

This article explores the EOT double girder crane structure, its key features, and the EOT crane working principle, highlighting why it’s a top choice for heavy-duty tasks.

Ⅰ What Is an EOT Double Girder Crane?

An EOT double girder crane, short for Electric Overhead Traveling Crane, is a robust lifting device that travels along tracks on a bridge framework to hoist and transport heavy loads. The “double girder” design refers to its two parallel main beams, offering superior load capacity, span adaptability, and height compared to single girder cranes. This makes it ideal for heavy-duty, long-span, and high-frequency operations.

Capable of handling loads from 5 to over 300 tons, depending on customization, the EOT double girder crane excels in demanding industrial settings. Unlike single girder cranes, which suit lighter tasks, double girder cranes are built for heavy-duty environments. These cranes comply with international standards like FEM (European Material Handling Federation), ISO 4301, and CMAA (Crane Manufacturers Association of America), ensuring reliability and safety.

Ⅱ Structure of an EOT Double Girder Crane

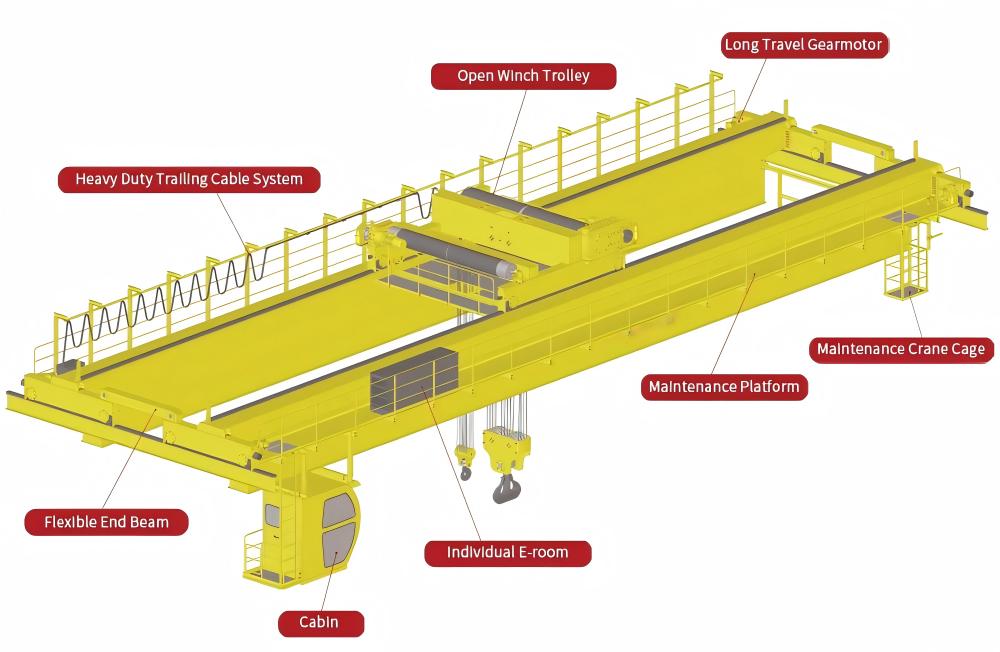

The EOT double girder crane structure comprises several key components that work together to deliver efficient lifting and movement. Here’s a breakdown of its main parts:

- Bridge Girders: Two parallel welded box or I-shaped beams form the primary load-bearing structure, providing exceptional rigidity.

- End Carriages: Located at both ends of the girders, these connect the crane to the runway tracks. They include wheels, motors, and gearboxes for smooth movement.

- Crab/Trolley: A mobile unit running along the top of the girders, equipped with a hoisting mechanism for precise load positioning.

- Hoisting Mechanism: Comprising a motor, gearbox, wire rope hoist, or winch, this system handles vertical lifting and lowering of loads.

- Electrical System: Powers the crane, featuring a control panel, festoon system, or conductor bars. Modern systems often include Variable Frequency Drives (VFD) for precise speed control.

- Control Cabin/Remote Control: Offers flexible operation options, such as a fixed cabin or wireless remote, enhancing safety and convenience.

- Safety Devices: Includes buffers, limit switches, overload protectors, anti-collision sensors, and emergency stop systems to ensure safe operation.

The diagram below illustrates the typical layout of an EOT double girder crane, offering a clear view of its design.

Ⅲ Main Features and Advantages

The double girder overhead crane features make it a standout choice for heavy-duty material handling. Here are its key benefits:

- High Load Capacity: Handles loads from 5 to over 300 tons, perfect for heavy material transport.

- Stable Operation: The double girder design ensures superior rigidity, minimizing load sway for smooth performance.

- Wide Span Coverage: Spans exceeding 25 meters, ideal for large factories or facilities.

- Advanced Technology: Integrates VFD and anti-sway systems for enhanced precision and safety.

- Customizable Design: Tailored options like explosion-proof features or specialized hooks meet diverse industry needs.

- Superior to Single Girder Cranes: While single girder cranes suit lighter tasks (15-20 tons), double girder cranes excel in high-intensity, continuous heavy-duty operations (D+ or E-class duty).

These double girder overhead crane features deliver unmatched efficiency, reliability, and long-term cost savings.

Ⅳ Applications of Double Girder EOT Cranes

Thanks to its robust load capacity and versatility, the EOT double girder crane is widely used across industries:

1.Steel Mills: Handles molten metal, steel coils, and plates in high-temperature, harsh environments.

2.Mechanical Workshops: Supports assembly of large machinery, component lifting, and maintenance tasks.

3.Warehouses & Assembly Lines: Streamlines material flow, enabling efficient loading/unloading and faster production.

4.Power Plants & Shipyards: Facilitates turbine handling, equipment installation, and precise heavy lifting in shipbuilding.

In each application, the EOT double girder crane enhances productivity and safety, making it indispensable for industrial operations.

Ⅴ Maintenance and Safety Tips

Regular maintenance is critical to extending the lifespan of an EOT double girder crane and ensuring safe operation. Follow these practical tips:

- Inspect Structural Integrity: Regularly check welds and bolted connections on the main girders for cracks or loosening.

- Wire Rope and Hoist Maintenance: Examine wire ropes for wear, broken strands, or corrosion, and lubricate gears and bearings regularly.

- Motor and Electrical System Care: Clean and test motors, gearboxes, and electrical components to ensure VFD systems function properly.

- Safety Device Testing: Routinely verify limit switches, overload protectors, and anti-collision devices to meet ISO 4301 standards.

Always adhere to rated load limits and ensure operators receive professional training. Schedule annual inspections by certified professionals. HSCRANE offers comprehensive maintenance services to keep your crane in peak condition.

The EOT double girder crane is a cornerstone of modern industrial operations, delivering unmatched load capacity, flexibility, and efficiency. From steel mills to assembly lines, its ability to handle heavy-duty tasks in demanding environments makes it a game-changer. Selecting the right crane model depends on your specific application, load requirements, and span needs.

HSCRANE provides tailored solutions to meet your unique demands. Visit our EOT double girder crane product page or contact us today to elevate your operations!

Recent Post