Blog

- Home

- Blog

How to Effectively Reduce the Total Cost of Ownership (TCO) of Overhead Cranes: A Complete Guide

When planning or purchasing an overhead crane, many companies tend to evaluate mainly based on the equipment price. However, in actual operation, what truly determines the return on investment is not the purchase cost, but the Total Cost of Ownership (TCO) throughout the entire lifecycle of the equipment. TCO is the key metric for measuring the long-term value of an overhead crane. It includes not only the initial purchase cost but also installation and commissioning expenses, daily energy consumption, routine maintenance costs, spare parts usage, and even more implicit costs such as downtime losses. Considering that an overhead crane typically operates for 10–25 years, these long-term costs often exceed the initial purchase cost and have a significant impact on production efficiency, operational stability, and return on investment (ROI).

For this reason, TCO management has become a crucial basis for equipment selection and investment decisions across industries. Through optimized equipment design, scientific model selection, reliable maintenance strategies, and intelligent lifecycle management, enterprises can effectively extend equipment life and achieve higher overall returns.

Key Factors Affecting the TCO of an Overhead Crane

The Total Cost of Ownership (TCO) of an overhead crane is influenced by multiple factors that span the entire lifecycle—from design and manufacturing to operation and maintenance. Understanding and optimizing these factors is essential for reducing long-term costs.

Structural design and material selection: A well-engineered structure and high-strength materials improve the overall lifespan of the crane, reduce self-weight, lower energy consumption, and minimize structural fatigue. This significantly reduces long-term maintenance and replacement costs. Poor structural design or overly simplified construction, on the other hand, may lead to frequent repairs and costly downtime.

Durability of mechanical components: Critical components determine the reliability of the overhead crane and the associated maintenance expenses. High-durability brakes, inverters, wire ropes, and other key parts reduce unexpected failures, extend replacement intervals, and lower spare parts costs and downtime over the crane’s lifetime.

Drive system efficiency and energy consumption: The drive system is a central contributor to operational costs. High-efficiency motors and frequency-control systems reduce energy use, minimize wear on mechanical components, and lower annual operating expenses. Inefficient drive systems, however, result in higher long-term energy costs and more frequent maintenance.

Application of automation and intelligent technologies: Smart monitoring, condition detection, fault prediction, and automatic positioning significantly reduce operational risks, enhance precision, and support predictive maintenance. These technologies help prevent breakdowns and downtime, leading to substantial long-term savings in maintenance and repair costs.

Operating environment (humidity, high temperature, corrosive conditions, etc.): Harsh working environments accelerate corrosion and component aging, requiring higher protection levels and improved materials. Selecting an overhead crane with insufficient environmental protection leads to frequent failures, corrosion issues, and elevated maintenance expenses.

Operator skill level and training: Well-trained operators can reduce shock loads, avoid misuse, and extend equipment lifespan. Inexperienced or untrained operators often cause improper operation, resulting in damage, failures, safety risks, and increased maintenance and downtime costs.

Strategies to Reduce the Total Cost of Ownership (TCO) for Overhead Cranes

To effectively reduce the Total Cost of Ownership (TCO) of an overhead crane, optimization must be implemented across every stage—from selection, design, installation, operation to long-term maintenance.

Strategies in the Early Selection Stage

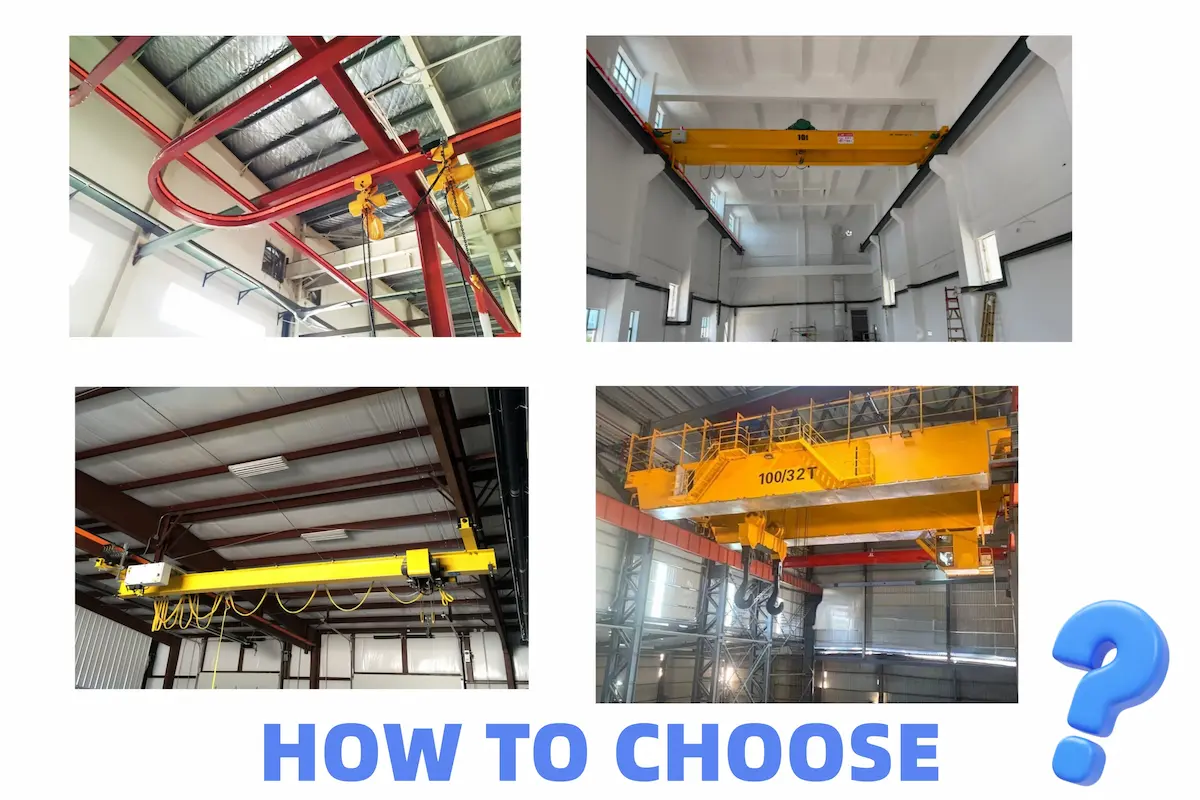

The selection phase is critical to determining the crane’s lifecycle cost. Choosing the right configuration can prevent many potential long-term expenses.

Select a configuration suited to the operating conditions: Different industries and environments demand different performance levels. Crane selection should match working class, duty cycle, load characteristics and travel patterns to avoid excessive wear and unnecessary maintenance.

Use high-grade components for heavy-duty or frequent operations: In demanding environments, high-quality brakes, travel mechanisms and wire ropes significantly reduce failure rates, extend service life and minimize downtime. Although initial investment is higher, long-term OPEX is substantially reduced.

Avoid over- or under-specification through customized design: Oversized equipment increases purchase and energy costs, while undersized equipment leads to frequent repairs and shorter lifespan. Customized solutions ensure parameters precisely match operational needs, effectively lowering TCO.

Choose branded components with long-term spare parts availability: Reliable brands ensure stable performance and consistent availability of spare parts, preventing downtime caused by supply disruptions and reducing long-term replacement costs.

Cost-Saving Approaches in Design & Manufacturing

Design and manufacturing quality directly impact energy consumption, equipment lifespan, maintenance needs and long-term operating costs.

High-strength steel and optimized structure reduce deadweight: Lightweight designs lower energy consumption and reduce load on runway structures, extending crane service life and minimizing operational costs.

Use high-efficiency motors and VFD systems: High-efficiency motors reduce power consumption, while VFDs provide smooth starts and precise control, reducing mechanical shock and wear.

Smart monitoring systems (condition monitoring, fault prediction): Embedded sensors analyze real-time data to detect abnormalities early, enabling predictive maintenance and preventing unexpected shutdowns.

Enhanced anti-corrosion and surface treatment: For humid, corrosive or dusty environments, advanced coatings, galvanization and protective sealing significantly reduce corrosion and maintenance costs.

Optimizations During Installation & Commissioning

Quality installation ensures the crane operates at its best from day one, reducing the risk of costly future corrections.

Standardized installation reduces rework: Ensuring proper assembly of the bridge, runway and power supply prevents later structural corrections and unnecessary labor costs.

Precise commissioning reduces energy consumption and wear: Accurate calibration of speed, braking distance and synchronization improves efficiency and minimizes mechanical stress.

Control bridge alignment and runway accuracy: Proper track levelness and bridge alignment ensure smooth operation. Excessive deviation leads to uneven wheel loads, increased wear and higher maintenance cost.

Reducing Operating Costs During Use

Proper usage significantly decreases wear, reduces energy consumption and improves safety.

Operate correctly (avoid shocks and overloads): Improper operation causes structural impact and overload damage, accelerating wear and increasing failure rates.

Optimize work cycles to reduce unnecessary operation: Reducing idle travel and optimizing lifting/transport rhythm increases energy efficiency and reduces fatigue on components.

Provide regular operator training: Skilled operators minimize mis-operation, prevent avoidable failures and reduce downtime costs.

Maintenance Strategies to Minimize Long-Term Costs

Maintenance is a major determinant of TCO. Scientific maintenance greatly reduces failures and extends lifespan.

Implement preventive and predictive maintenance: Preventive maintenance avoids accumulation of small issues, while predictive maintenance uses condition data to identify failures early—improving cost efficiency.

Regular inspection of critical components (brakes, ropes, bearings): These components directly impact safety and performance. Regular inspection prevents sudden failures and costly downtime.

Use intelligent monitoring to reduce unexpected shutdowns: Real-time monitoring of temperature, vibration, current and motor load helps identify trends and issue warnings before breakdowns occur.

Optimize spare parts inventory: Maintaining proper inventory ensures quick repair, avoids waiting time and reduces downtime costs.

Emerging Technology Trends for Lower TCO

As industrial digitalization accelerates, technologies that reduce TCO are becoming increasingly mainstream.

Smart and remote monitoring: Real-time data collection, anomaly detection and early warning greatly reduce unexpected downtime and maintenance costs.

Digital twin technology: Simulating the full lifecycle performance enables more accurate lifespan prediction, optimized maintenance and improved component durability.

Energy-efficient drive systems and energy recovery technology: These systems reduce power consumption and mechanical wear, lowering operating expenses.

Modular design: Modular key components enable faster replacement and maintenance, shorten downtime and improve maintainability.

Together, these trends push overhead cranes toward higher efficiency, lower operating costs and longer lifecycles—delivering stronger TCO optimization for industrial users.

How Enterprises Can Evaluate and Continuously Optimize Overhead Crane TCO

|

Strategy |

Specific Actions |

Impact on TCO |

| Establish a TCO Evaluation Model | 1. Quantify procurement, installation, operation, maintenance, energy consumption, downtime, and spare parts costs. 2. Predict costs under different operating conditions and equipment models. | Helps enterprises fully understand lifecycle costs, enabling scientific equipment selection and investment decisions. |

| Monitor Key Cost Indicators | 1. Set KPIs for failure rate, energy consumption, maintenance frequency and downtime. 2. Conduct regular data review and analysis. | Allows early detection of abnormal cost trends and optimizes operational strategies to reduce potential expenses. |

| Data-Driven Continuous Improvement (PDCA Cycle) | Plan: Develop TCO optimization strategies. Do: Implement real-time improvement measures. Check: Continuously monitor improvement results. Act: Adjust strategies based on feedback. | Enables continuous optimization of equipment management and operations, lowering long-term operating costs and increasing ROI. |

| Establish Long-Term Cooperation with Equipment Suppliers | 1. Sign long-term service and spare parts supply agreements. 2. Share equipment data for technical support. 3. Collaborate on equipment configuration and maintenance optimization. | Reduces procurement and maintenance costs, ensures spare parts availability, minimizes downtime, and keeps costs under control. |

How HSCRANE Helps Reduce Overhead Crane TCO

Lifecycle-Oriented Design Philosophy: From structural design to component selection, HSCRANE prioritizes durability and ease of maintenance from the design stage—significantly reducing long-term service and maintenance expenses.

Energy-Efficient Drive and Control Systems: High-efficiency motors and advanced VFD systems ensure smooth starts, precise motion control and lower mechanical wear—reducing energy consumption and long-term operating costs.

High Reliability with Minimal Downtime: Using premium components and redundancy-enhanced designs, HSCRANE cranes achieve high stability and low failure rates, effectively reducing unplanned downtime and associated production losses.

Smart and Digital Value-Added Services: Intelligent monitoring, status prediction, early warning and operational analytics support predictive maintenance and remote management, lowering maintenance costs and minimizing failure risks.

Customized Solutions That Prevent Over- or Under-Specification: HSCRANE provides precise configuration based on the actual working environment, avoiding unnecessary equipment oversizing or undersizing—ensuring maximum investment efficiency.

Comprehensive After-Sales Support & Spare Parts Supply: Standardized maintenance programs, fast spare parts delivery and systematic inspections help reduce maintenance complexity, shorten downtime and further lower TCO.

Reducing the Total Cost of Ownership (TCO) of an overhead crane is not achieved through a single action—it is a systematic optimization across the entire equipment lifecycle. Every decision—from equipment selection, design and manufacturing, installation and commissioning, to daily operation and maintenance—directly impacts energy usage, reliability and service costs. Only through holistic and lifecycle-based optimization can enterprises achieve high-value investment returns and long-term operational stability.

Contact HSCRANE, get a cost-optimized overhead crane solution and start reducing TCO from the moment you make your purchasing decision.

Want to further improve crane efficiency and safety? Click to view Crane Safety Guidelines: Crane Safety Guidelines: Essential Rules for Overhead Crane Operation.

Recent Post