Blog

- Home

- Blog

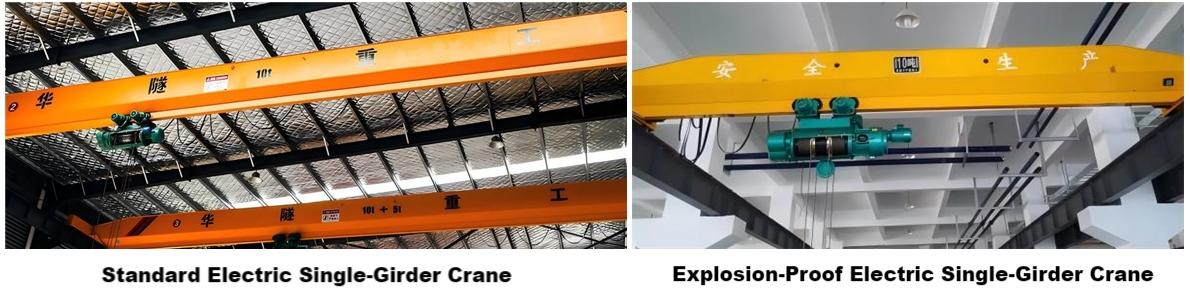

Standard Cranes vs Explosion-Proof Cranes: Key Differences and Applications

In modern industrial development, cranes are indispensable material handling equipment in factory manufacturing and production processes. Beyond the standard cranes commonly used in workshops or warehouses, cranes have gradually evolved into a diverse and extensive family to meet different usage environments, types of materials, and specific operational requirements. Today, we will share the key differences between standard cranes and explosion-proof cranes.

1. Different Design Standards:

Standard Cranes:

Designed according to general crane standards such as GB/T, FEM, ISO, CMAA, primarily aimed at improving production efficiency and load capacity in factories. They are suitable for ordinary environments without fire or explosion risks, such as factory workshops, warehouses, and construction sites.

Explosion-Proof Cranes:

Designed in compliance with explosion-proof standards such as GB3836, IECEx, and ATEX, meeting the classification requirements of various hazardous zones. They are intended for dangerous environments and special operational conditions.

Source reference: http://www.csres.com/

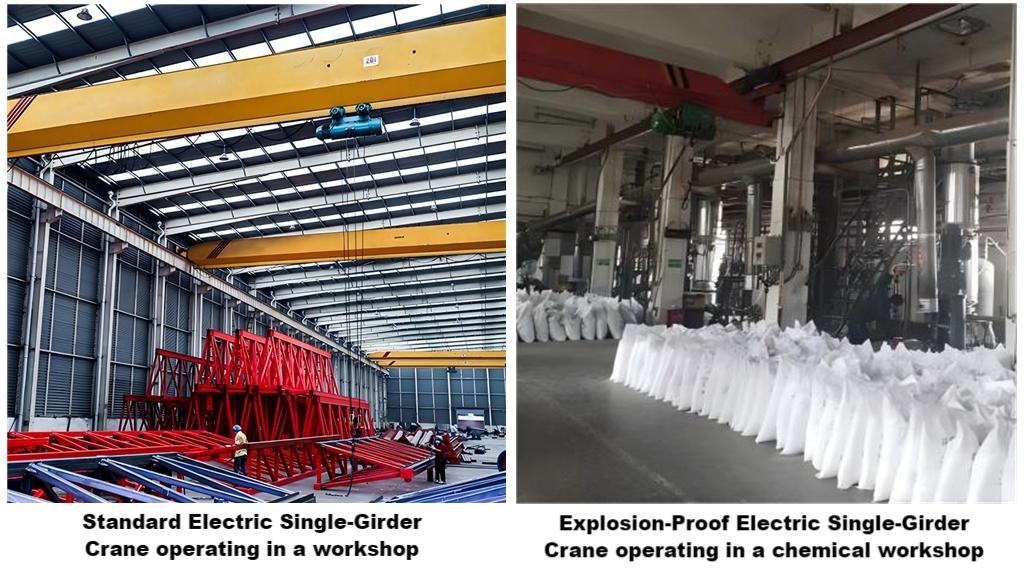

2. Different Application Scenarios:

Standard Cranes:

Suitable for general industrial production environments such as machining factories, logistics warehouses, construction sites, and port terminals, where there are no flammable or explosive substances.

Explosion-Proof Cranes:

Specifically designed for environments with explosion hazards. Depending on the type of hazardous material, they can be classified as:

Gas Explosion-Proof: For areas containing flammable and explosive gases such as methane, propane, or gasoline vapors (e.g., gas stations, chemical tank zones).

Dust Explosion-Proof: For areas containing combustible dust such as flour, aluminum powder, or coal dust (e.g., grain processing plants, powder metallurgy workshops).

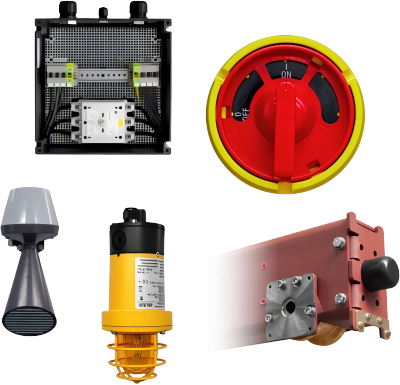

3. Differences in Key Components:

| Component | Standard Crane | Explosion-Proof Crane |

|---|---|---|

| Motor | Conventional asynchronous motor; may generate sparks or high temperatures during operation. | Explosion-proof motor (e.g., flameproof or increased-safety type); casing can withstand internal explosions and prevent flame leakage, avoiding contact with flammable or explosive media. |

| Electrical System | Regular cables, switches, and contactors with no special explosion-proof treatment. | Explosion-proof cables (flame-retardant, anti-static), explosion-proof switches/contactors; junction boxes use flameproof design to prevent sparks from escaping. |

| Transmission System | Standard gears and bearings; lubricants have no special requirements. | Gear meshing uses anti-static materials; bearings use low-friction lubricants to avoid spark generation; some components made of copper alloys (non-sparking). |

| Braking System | Conventional brakes; friction may produce sparks. | Explosion-proof brakes, using non-sparking materials (e.g., copper-based powder metallurgy); brake pads do not produce visible sparks. |

| Metal Structure | Ordinary steel with no special surface treatment. | Some components coated with anti-static layers to prevent static accumulation; structural joints can be grounded to release static electricity. |

Explosion-Proof Crane Components

4. Different Safety Standards:

Standard Cranes:

Must comply with general crane safety standards, such as China’s GB/T 3811 “Crane Design Code” and GB 6067 “Safety Regulations for Cranes”.

Explosion-Proof Cranes:

In addition to general standards, they must meet explosion-proof specific standards, such as China’s GB 3836 (Electrical Equipment for Explosive Gas Atmospheres) and GB 12476 (Electrical Equipment for Combustible Dust Atmospheres), and obtain national explosion-proof certification (e.g., Ex certification) to be safely used in hazardous environments.

Source reference: http://www.csres.com/

5. Differences in Maintenance Standards and Operational Requirements:

Standard Cranes:

Maintenance focuses on mechanical performance (e.g., lubrication, structural integrity) and electrical system functionality. Operations have no special explosion-proof restrictions.

Explosion-Proof Cranes:

Maintenance must strictly follow explosion-proof crane maintenance regulations, including:

- Do not replace explosion-proof components (e.g., motors, switches) arbitrarily.

- Regularly inspect the sealing of explosion-proof surfaces (e.g., flameproof gaps) to prevent failure due to wear.

- Operators must receive explosion-proof training, and actions that could trigger explosions (e.g., unauthorized repairs, impacts on equipment) are strictly prohibited.

6. Differences in Price:

Standard Cranes:

Lower cost and shorter delivery times.

Explosion-Proof Cranes:

Due to stricter requirements for electrical systems, materials, and manufacturing processes, the cost and price are typically 1.5 to 3 times higher than standard cranes.

7. Differences in Hoists Used:

Hoists used on explosion-proof cranes must also have explosion-proof features. Compared to standard hoists, the differences include:

| Comparison Item | Standard Hoist | Explosion-proof Hoist |

|---|---|---|

| Working Environment | Used in normal factories, warehouses, workshops without explosive hazards. | Used in petrochemical, coal mine, natural gas, military, dust and other hazardous environments. |

| Design Standard | Manufactured according to GB/T, ISO, FEM standards. | Manufactured according to GB3836, ATEX, IECEx explosion-proof standards. |

| Explosion-proof Grade | No explosion-proof requirement. | Common grades: Ex d IIB T4 (gas), Ex tD A21 IP65 T135℃ (dust). |

| Motor | Standard motor, IP54/IP55, insulation class F. | Explosion-proof motor, IP55/IP65, class F/H insulation, anti-spark and overheat protected. |

| Electrical Control | Standard control box and pendant. | Explosion-proof control box, pendant, junction box to prevent ignition. |

| Mechanical Structure | Hook, pulley made of standard steel. | Parts with friction (hook bushing, pulley bushing) use copper alloy or anti-spark material. |

| Surface Treatment | Standard painting. | Anti-static and anti-corrosion coating, surface resistance meets explosion-proof requirements. |

| Lifting Capacity | Typical 0.5t ~ 50t. | Typical 0.5t ~ 20t (limited by explosion-proof motor and structure). |

| Lifting Speed | Single or dual speed, 48 m/min. | Single or dual speed, 36 m/min (slower for safety). |

| Price | Lower cost, shorter lead time. | Higher cost (1.5–2.5 times standard), longer delivery time. |

Summary:

Standard cranes are general-purpose material handling equipment, designed primarily for efficient lifting and transport of goods. Explosion-proof cranes, on the other hand, are specialized equipment for hazardous environments, with their core design and materials aimed at eliminating ignition sources to ensure safe operation in explosive atmospheres. Naturally, explosion-proof cranes come at a higher cost.

When selecting a crane, it is essential to match the equipment type strictly to the working environment and assess whether the materials or processes involve explosive risks or mandatory explosion-proof requirements, in order to prevent safety accidents.

Appendix:

Applicable Environments and Classification of Explosion-Proof Cranes

Explosion-proof cranes are suitable for the following environments:

Class I: Methane environments in coal mines

Class II: Explosive gas mixture environments

Class III: Explosive dust and fiber environments

Class I is not further subdivided. Classes II and III are classified in more detail as follows:

| Category | Name | Specific Component |

|---|---|---|

| II A | Explosive Gas Atmosphere | Propane |

| II B | Ethylene | |

| II C | Hydrogen | |

| III A | Explosive Dust Atmosphere | Combustible Fluff |

| III B | Non-conductive Dust | |

| III C | Conductive Dust |

Classification of Explosive Gas and Dust Environments

Explosive gas and dust environments are further classified based on the frequency and duration of the presence of hazardous substances:

Zone 0 / Zone 20

Zone 1 / Zone 21

Zone 2 / Zone 22

| Type of Explosive Environment | Hazardous Area Classification | Explosion-Proof Equipment Category |

|---|---|---|

| Coal Mine Gas Environment | Single hazardous area, no further subdivision | Category I |

| Explosive Gas Environment | Zone 0 / Zone 1 / Zone 2 | Category II |

| Explosive Dust Environment | Zone 20 / Zone 21 / Zone 22 | Category III |

Detailed Definition of Hazardous Zones

Zone 0:

Locations where explosive gas atmospheres are continuously present or present for long periods.

Zone 1

Locations where explosive gas atmospheres are likely to occur during normal operation.

Zone 2

Locations where explosive gas atmospheres are not likely to occur in normal operation, and if they do, they are infrequent and of short duration.

Zone 20

Locations or inside containers where combustible dust is continuously present or frequently occurs in quantities sufficient to form a combustible dust–air mixture and/or an uncontrollable, thick dust layer.

Zone 21

Locations where, during normal operation, combustible dust may occur in quantities sufficient to form a combustible dust–air mixture, but not included in Zone 20.

This zone also includes areas adjacent to points of dust charging or discharging, where dust layers during normal operation may create combustible dust–air mixtures.

Zone 22

Locations where combustible dust clouds may occasionally occur under abnormal conditions and exist only for a short time, or where dust occasionally accumulates or forms layers that may create a combustible dust–air mixture.

If the possibility of dust accumulation or dust layers cannot be excluded, the location should be classified as Zone 21.

In summary, standard cranes vs explosion-proof cranes both play crucial roles in modern industrial operations.

Standard cranes handle over 70% of global workshop material handling tasks (CMAA 2023). They are cost-efficient, highly versatile, and ideal for manufacturing, logistics, and infrastructure projects.

Explosion-proof cranes, on the other hand, are critical for safety in hazardous environments. They are widely used in chemical, petrochemical, mining, and grain processing facilities.

Studies from IECEx show that adopting explosion-proof lifting equipment can reduce the risk of major incidents by more than 60% (IECEx 2023).

Companies should carefully evaluate their production environment and safety standards. Choosing the right crane type will optimize both efficiency and workplace safety.

Choosing the right crane is critical for both efficiency and safety. HSCRANE has over 20 years of experience providing internationally compliant standard cranes and explosion-proof cranes.

Our products serve over 200 companies worldwide in industries such as metallurgy, chemicals, logistics, and energy. We deliver tailored solutions for every working environment.

Whether you need a cost-effective standard crane or a high-safety explosion-proof crane, HSCRANE has you covered. Contact us today for expert advice and a customized quote.

Recent Post